Learn everything you need to know about performing physical counting inventories, including the steps, methods, process, planning and benefits. Plus, expert advice, calendars and metrics to help you become an inventory pro.

Video: What Is a Physical Inventory Count?

What Is a Physical Inventory Count?

A physical inventory count is a structured approach to counting a company’s stock where staff uses a predetermined method to count the goods. Companies schedule a physical inventory count at the end of a reporting period.

The Four Types of Physical Inventory Counts

There are four types of inventory counts: manual, electronic, cycle counting and full inventory counting. The methods vary but choosing the right technique can be the difference between good and bad data for your company.

Pros and Cons of the Types of Inventory Counts

| Physical Inventory Method | Description | Pros | Cons |

|---|---|---|---|

| Manual Completion | This count uses paper count cards or sheets and pencils to record inventory. | Low cost for materials | High rate of errors |

| Electronic Counting | This count can use scanners, RFID, barcodes or mobile devices. | Cuts down significantly on counting errors. | This method still takes extra time and resources to complete. |

| Cycle Counting | Staff count random portions or rotating sections of the inventory at any given time. | It cuts down on extra time or resources necessary to count, and companies may not need to stop operations during counts. | Depending on the cycle counting method, some companies count inventory less than the ideal number of times. |

| Full Inventory | Companies repurpose staff or bring in temp staff to count all the stock at one time. | This method provides accurate inventory records for creating the annual financial document. | This method may require an operational shutdown and is labour- and time-intensive. |

Physical Inventory vs. Cycle Counting

A physical inventory is a comprehensive, often annual count of the stock a company has on-hand. Cycle counting is a more systematic method of counting portions of the stock. Companies sometimes conduct cycle counting as often as daily, and it’s advisable to perform them at least quarterly.

Physical inventory is not always automated. Cycle counting is typically automated, however. Automation streamlines the inventory process overall, whether physical or cycle counts. It saves time, eliminates most human error, and enables real time and useful data. The most accurate inventory counts are those that combine cycle counts with automation.

Annual Physical Inventory Count

Businesses usually perform their annual physical inventory count before compiling their annual financial reports. Performing inventory only once a year does not always yield the most accurate results. The best inventory count practice depends on your business type and goals.

The types of businesses that perform annual physical inventories include retailers, manufacturers, wholesale distributors and ecommerce-based companies. They can do a full inventory once or do cycle counting. In cycle counting, staff counts sections of stock on a rotating or systematic basis. Read our cycle counting inventory guide to learn more about this practice.

Even if you have an automated system that manages your inventory, experts agree that you need to perform at least some physical inventory. A computerised system cannot replace a physical inventory count. Businesses with small amounts of stock may still want to perform annual physical inventories.

Companies with large amounts of stock, such as distributors, find freezing stock to count inventory quite disruptive. Therefore, they may prefer implementing a perpetual inventory system to appease their auditors and reconcile their stock numbers, instead of a full annual count.

Benefits of Doing a Physical Inventory Count

Physical inventory counts are an essential part of keeping inventory records accurate and current. Up to date inventory records provide for better forecasts of sales and purchases and ensures you always have the right amount of product on hand.

Performing a physical inventory benefits your customers, and accurate physical inventory counts are a necessity. No end-user, be it consumer, reseller or wholesaler, wants to deal with uncertain stock levels in this modern day of instant gratification. Customer satisfaction is paramount. Updated inventory levels ensure that you can fulfill your orders for your customers promptly or tell them when it can be fulfilled.

Another benefit of physically counting your inventory is to ensure you understand and can plan for loss. Loss can come from theft or breakage. Every day that an item remains in inventory, its value decreases. As the value lessens, the risks of the cost to stock the item outweighing its value becomes very real.

Performing physical inventories improves your profits overall. You can classify certain products in your warehouse as obsolete inventory, which is a valuable method for identifying which items to market and merchandise for quick sale. This process also reduces the liability and break even, at least, for questionable products.

Award Winning

Cloud Inventory

Issues With Physical Inventory Count

The biggest problem companies cite about conducting physical inventories is that they take up a lot of time and resources. Some companies shut down parts or all operations to perform their physical inventory. When this happens, they risk poor customer service.

Some businesses do not have the staff to complete a full physical inventory.

Usually, discrepancies happen in a physical count because internal or temporary staff don’t accurately record some of the inventory, or they classify items or record new items incorrectly. Regardless of accuracy levels, there are some things staff should not be counting during the physical inventory. These include:

- Supplier receipts after the count’s decided-upon cut-off date

- Any known thefts

- Any known shipments that departed without invoices

Tips & Best Practices When Preparing for a Physical Count

The best way to perform a successful inventory count is through detailed planning. Using a comprehensive written policy and instructions decrease unknowns and streamline a physical inventory count.

Other tips to improve your staff’s counting accuracy include:

- Using scanners or other stock counting technology

- Selecting staff who are attentive counters

- Addressing discrepancies immediately

- Performing a mock count during the planning

- Ensuring the cost of the item counted is not displayed during the count

- Stopping operations when performing a complete physical inventory

- Ensuring that staff on-site during a full physical inventory are only there for the count

- Securing the stock area on the day of the inventory

- Using inventory software

Purpose of a Physical Inventory Count

A physical inventory can ensure an accurate inventory tally. Staff physically count each piece of stock. This physical inspection of goods should confirm what’s in the inventory management system report. Any discrepancy should alert you there’s another issue.

Businesses perform physical inventories for other reasons, such as when preparing a balance sheet for tax season. Additional objectives of an inventory count include:

- Check and Balance Inventory Levels: Physical inventories can help managers see any discrepancies between their inventory management system reports and what items are in their storage.

- Manage or Monitor Theft: The difference between what appears in the inventory management system, and what is present can be due to missing, stolen, lost or broken items. Unless staff manually enter when these scenarios occur, the system would not recognise them.

- Create an Accurate Budget: Companies with precise inventory counts can better plan their budget for the next year’s inventory orders.

- Report Accurate Earnings: An inaccurate inventory means a company will report an incorrect amount for the cost of goods sold, the gross profit and net income. Public companies are primarily accountable to their stakeholders to provide correct figures in their annual reporting.

The types of inventory stock that companies need to count physically include raw materials, works-in-process (WIP), finished goods, packing materials and maintenance, repair and operations (MRO). Using the right inventory metrics can help you measure the relative success of how your company stocks and manages these inventory categories. You can use inventory turnover as a metric of success for all of these categories. However, there are additional metrics that are good practice for each type of inventory. The chart below shows examples of which metrics are good practice, based on each category.

How to Measure the Success of Your Inventory Management Practice by Type of Stock

| Types of Inventory | Metric | Metric Formula | Benchmark for Metric |

|---|---|---|---|

| Raw Materials | Inventory Turnover Ratio | (Cost of goods sold for the year) / (Average value of month-end raw material inventory) | Top performers are at ~16.5 times per year. |

| Works-in-Process (WIP) | WIP Inventory/Turns | (Cost of goods sold) / (Average inventory used to produce the goods) | Compare this figure with previous years to evaluate performance. |

| Finished Goods | Order Cycle Time | Calculate the amount of time from when a customer places an order to when they receive their product. | Report this metric in days. Industry leaders are two to three days. |

| Packing Materials | Packing Costs | Add together packaging, boxes, filler, and overall labour costs. | This figure is different for every business, but each company should strive for constant improvements. |

| Maintenance, Repair and Operations | Inventory Accuracy | (The number of items listed as in-stock) / (The total found within spare part and raw material caches) | ~95% |

Step-by-Step Physical Inventory Count Instructions

Performing successful physical inventories requires appropriate planning, preparation and staff guidance. Involve managers in every step and have them provide advice and oversight to get the best results. Start planning your physical inventory at least three months in advance.

When providing counting instructions, you could use a written company policy that you always follow or prepare a new plan each year. Make sure you cover the following activities before any scheduled inventory count:

- Start with a Plan: If your company has one already, great. If you are making the plan, start by figuring out if your company is already controlling inventory with a periodic or perpetual inventory system. Read our “Essential Guide to Inventory Control” to learn the most efficient method to count your inventory based on where SKUs are located in your warehouse.

- Decide on the Interval Between Counts: As part of the plan, decide how often you will count inventory. An accurate record of inventory is required for tax purposes in publicly traded companies, but you can choose to count stock more often.

- Draft the List of Inventory Items to Count: This draft list should include stock quantities. Knowing this number should help you determine how long a physical inventory count will take.

- Select an Inventory Date: Ideally, this date you pick to do inventory has a minimal effect on your regular business operations, as physical inventory counts are time consuming. Choosing a time that won’t cause some workplace disruption isn’t always possible with bigger businesses or supplier-warehouses but try to pick a time that’s not particularly busy.

- Choose Who Will Take Inventory: Once you settle on an inventory date, figure out what staff can do the counting. One good practice is to perform a cost analysis of staff salaries and overtime to determine how much it costs to perform a count. It may be more economical to hire and train outside temporary help in large businesses. Outside supplemental staff can free up some of your regular staff to continue necessary operations.

- Select Staff Training Dates: In the same way you choose your inventory date, you need to choose one (or two, in the case of larger staff) dates to train staff on the inventory counting process. This training should occur no more than one week before the scheduled count, preferably the workday(s) right before the count.

- Notify Outside Partners and Storage Locations: Suppliers and partners should know well in advance if your physical count will affect their operations, so send a message with the date, time and how the count will affect them. Earlier communication allows your partners to contact you with questions and concerns.

- Notify Staff: Begin the process by notifying staff of the training and counting schedule. Decide, based on seniority or already-existing delineations, who will be on each counting team. Some companies prefer to pair an experienced staff member with a newer one.

- Order the Necessary Equipment: Whether your staff will use clipboards and pencils, count tags, or scanners, order them in enough time to arrive for training. Count tags are heavy cards with sequential numbering stamped on the top and bottom that counters use to track inventory.

- Check Your Electronic Equipment: If you’re using electronic counting equipment, plan to check it well before the count. You may need to order parts, change batteries or charge devices.

- Review Any Apps and Software: Don’t forget about software updates! If you are planning to use apps or inventory software, verify that your staff is using the most current version.

- Preview the Inventory: Take a walk around the stock room or warehouse. You may get ideas about how to decrease any challenges the counters may face. For example, there may be temporary physical barriers that can slow them down.

- Prepare the Space for the Inventory Count: Designate any additional areas needed for counting or staff. For example, if you will pull out small parts to count in this area, set up bins to use during the count. The inventory area should be free from any clutter or trash.

- Do an Inventory Clean-Up: Storage areas should always be the neatest area in any warehouse. However, there should not be any products waiting to be put away or out of their normal storage area.

- Identify Stock That’s Not in the Count: Use signs to show stock that’s not in the count. It is easy for staff to become confused during a long session and start counting these items without clear markings.

- Prepare Your Final Item Count List: Create a final version—including quantities—of your initial inventory list that staff will count.

- Train Staff on the Procedure: Staff will need written instructions on how to perform the count. Consider any contingencies that may happen, such as duplications, missing items and those in the wrong place. Decide how to handle these scenarios in advance. For example, staff may encounter the wrong product in a location. Decide whether they should stop their count and report back in, fill out a new card for the item present and count it or investigate the discrepancy.

- Train Staff on the Equipment: During this same training, if you’re using count cards, teach staff how to complete them. If you’re using electronic equipment like scanners, train the team on how to use all the functions necessary and troubleshoot any equipment issues. Include directions about what they should do if the equipment malfunctions.

- Perform a Demonstration: During the training, a demonstration of how to count the stock is helpful for staff.

- Stop Entering Data Before the Count: Before printing the line item list for counting, be sure to freeze any data entry in the inventory management system to decrease discrepancies.

- Pre-Count the Inventory: If possible, pre-count some pieces of the stock as a sort-of dry run. Look for counting issues and annotate if the pre-count area needs recounting or if you consider it complete.

- Print the Count List: If you are using pencil and paper, print the final list the evening before or the morning of the count to ensure you capture any last-minute details.

- Freeze Other Activities: In the case of a full count, freeze any other company activities related to inventory. In other words, do not receive or adjust any stock in the company until the count is completed and reconciled.

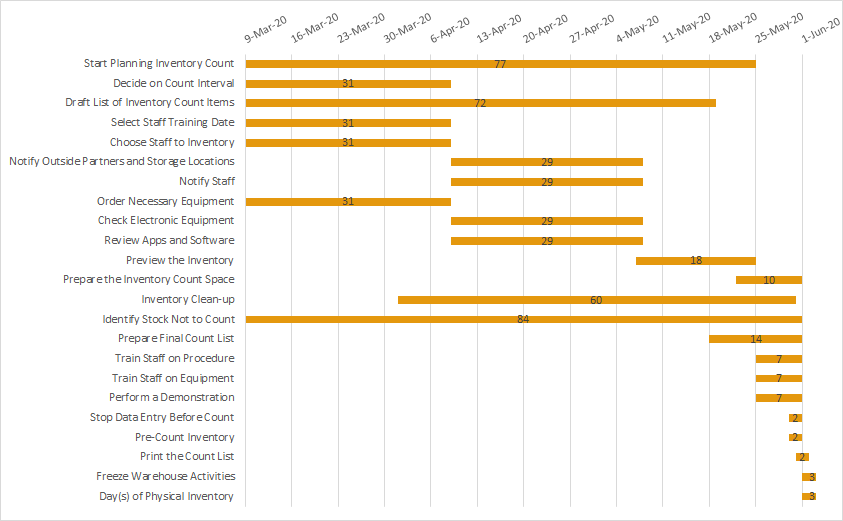

The example chart below shows one physical inventory count, lasting three days. This scenario is for a large company or a supplier-warehouse. As you can see, staff start planning the physical count 12 weeks in advance.

Example of Physical Inventory Count Steps in Days

The Physical Inventory Counting Process

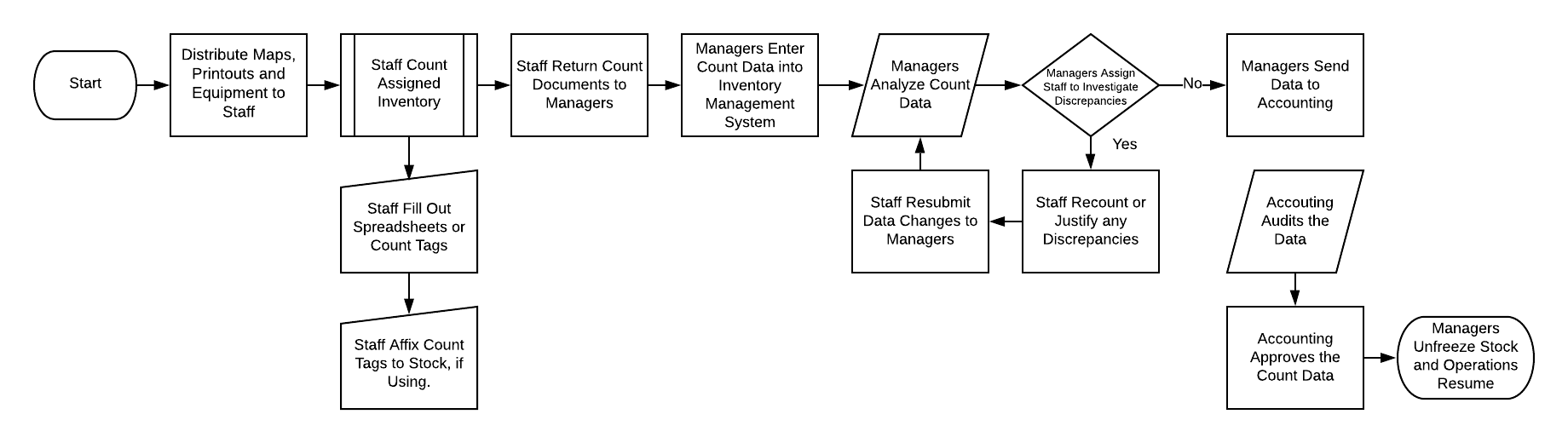

After producing a detailed, appropriate inventory counting plan, it’s time to execute the physical inventory process. Assign a supervisor to each team of counters to whom they report and all the equipment they need.

The process on the day of the count begins with the managers freezing the inventory items. They should also have printouts of the list of inventory that will get counted. The next steps in a physical inventory count are:

- Assign maps, inventory to-be-counted printouts, and equipment to staff.

- Staff counts the assigned inventory.

- Staff fills out spreadsheets or count tags.

- Staff returns the spreadsheets or count tags to the managers. If the staff is using count tags, they affix the top portion of the tag to the stock or stock holding area.

- Managers enter the data into the inventory system.

- Managers compare counting data to data in the system.

- Managers compare data against yield & pack reports.

- Managers assign staff to investigate any discrepancies.

- Staff recount or justify the discrepancies.

- Staff resubmits any data changes to managers.

- Once managers validate the count data, they send it to the accounting department.

- Accounting audits the inventory count data.

- Accounting approves the inventory count.

- Managers unfreeze the stock and return to normal operations.

Flowchart of Physical Inventory Count Process

Use your regular warehouse or storage area map and delineate the areas where each count team will work. Notice how the blown-up section in the image below shows the labeling of each storage space. Assign staff to specific locations.

Warehouse Layout Map for Inventory Day

A typical count includes the location, item description, part number, quantity present and unit of measure. Staff should verify any tags still on items and their information. Auditors should follow up with each section counted as soon as the team completes it. Random checks throughout the process are also a good idea. Finally, reward the staff for their part in the inventory. Although an inventory is essential, it may not be your staff’s favourite activity.

After the count comes the exciting part: the analysis. If your study shows any stock irregularities, assign an investigation. Pinpoint any zones in your storage that are high-risk, or more likely to have anomalies. Determine any additional metrics you will report, such as inventory turnover. For more information on inventory turnover, read “Inventory Turnover Primer: Calculations, Rates and Analyses.”

How to Streamline Physical Inventory Counts With NetSuite

Counting inventory is a fact of doing business. Using an inventory management system can help ensure you always have the right amount of stock at the right locations to meet customer demand. NetSuite’s inventory and warehouse management solution has all the tools inventory managers need to help them track and locate stock at a moment’s notice. The system supports all the essential future-forward features such as AI, VMI, and mobile device integration.

NetSuite’s Inventory Count feature improves inventory tracking and provides increased control over key assets. Companies can categorise inventory based on the volume of transactions and/or value and enter regular periodic counts of on-hand item quantities to maintain inventory accuracy.

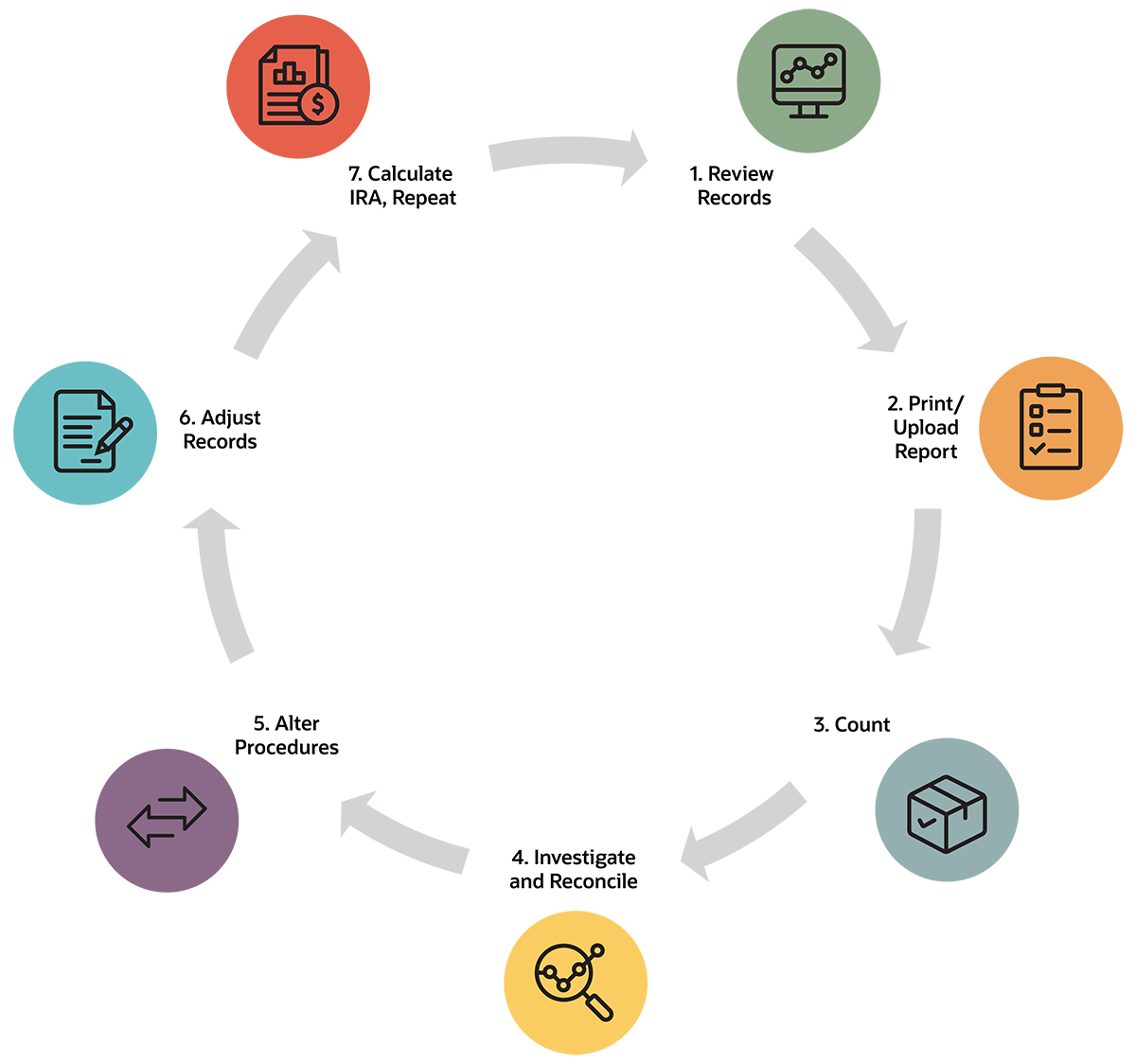

While physical counting once a year may seem like a good option, cycle counting is less disruptive and provides more visibility into stock daily. Using an inventory management system and warehouse management system with regular cycle counts gives companies more accurate inventory levels; automatic prompts for items that need to be counted; the ability to categorise items based on volumes or value; improved quality assurance; and higher customer satisfaction rates. Using cycle counting makes discrepancies smaller and smaller with each count. Reconciliation is also easier.

Learn more about NetSuite’s inventory management solution.