Supply chain planning helps your business meet customer demand in the most efficient way possible. But to increase profitability and keep demand from outstripping supply, every step in the supply chain planning process—from ordering raw materials to product delivery—has to be reliable.

The process also has to be adaptable, efficient and accurate to address changing market forces. It sounds like a tall order, but there are best practices that can help.

Video: What is Supply Chain Planning (SCP)?

What is Supply Chain Planning?

Supply chain planning helps you match product supply with customer demand using forecasting, pricing strategy and inventory management techniques. Before delving into the details of supply chain planning, here are two key concepts you need to know.

Supply chain planning vs. supply chain execution

Supply chain planners are long-term prognosticators, asked to peer months or even years into the future. But their predictions aren’t based on what they see in crystal balls. Instead, they analyse manufacturing, logistics and inventory data to make their plans.

Supply chain execution, on the other hand, is the day-to-day implementation of that plan—order fulfillment, transporting goods, warehousing. Think of them as two sides of the same coin.

What is supply chain management software?

Supply chain management software supports planning and execution. It forecasts demand and manages inventory so you can keep costs down and deliver products faster. It provides real-time updates about the status of your supply chain, lets you inspect your operations and helps balance supply with demand.

Supply Chain Benefits

Supply chain planning is a way to improve your operations by standardising procedures, reducing waste and planning for variability.

It also plays a pivotal role in price and delivery—two of the most important aspects of customer satisfaction. A well-run supply chain lowers manufacturing costs, improves the reliability of deliveries and helps you respond to unplanned demand.

Importance of Supply Chain Planning

Supply chain planning affects your top and bottom lines. Stock shortages can result in lost sales or rush shipping charges. Too much inventory ties up cash. And over-forecasting and canceling orders can damage important relationships with suppliers and disrupt your own business.

It’s difficult to argue with the why, but there’s often less agreement on how the process should be structured.

Supply Chain Planning Process

Achieving desired business benefits requires strategic, long-range supply chain planning. However, in a flexible supply chain, managers are empowered to respond tactically to changing conditions and alter those plans on the fly.

Strategic planning:

This phase focuses on the long term and establishes a framework for your supply chain. In this phase, you’ll factor in elements like the location of your business and suppliers. You’ll map transportation routes and determine the size and location of warehouse space for materials and finished products. If you already have a location, this is when you determine how to leverage it.

Tactical planning:

The next phase delves deeper into individual aspects of this framework. For example, you might place standing purchase orders with certain suppliers for just-in-time delivery. You may decide to store safety stock of key materials to avoid shortages. And even the best-laid plans can require tactical adjustment, such as changing sourcing strategy or rebalancing inventory among overseas warehouses if new tariffs raise your costs, for example.

Supply Chain Strategies and Methods

Many planners use a combination of just-in-time delivery and safety stock to cut costs while hedging against shortages. The just-in-time approach delivers materials right before they are needed for manufacturing or other processes. With less inventory, less cash and space are tied up.

But companies risk pauses in production if there are delays in shipping or problems with materials. Alternatively, with the safety stock approach, companies store more inventory to provide an extra buffer against supply chain disruptions; the downside is an increase in inventory costs.

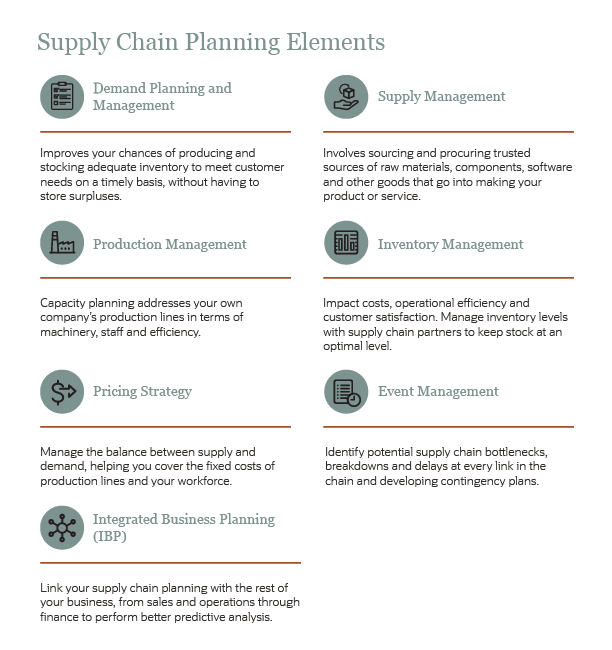

Supply Chain Planning Elements

A product requires supply chain planning at every phase of its life cycle. Steps include:

-

Demand planning and management: Accurately forecasting demand for a product improves your chances of producing and stocking adequate inventory to meet customer needs on a timely basis, without having to store surpluses. Supply chain planners look at historical customer behaviour, projected versus actual sales, market conditions and other factors. Increasingly, they use predictive analytics to better understand the demand for a particular product—how much, where and when it should arrive. Then, supply chain planners estimate the internal demands on each link in their supply chains.

-

Supply management: Supply management involves sourcing and procuring trusted sources of raw materials, components, software and other goods that go into making your product or service.

-

Production management: In parallel, capacity planning addresses your own company’s production lines in terms of machinery, staff and efficiency. The key question: How much can we realistically produce during the planning period? Keep in mind that this could be less than your demand forecast.

-

Inventory management: How a company orders, handles and stores goods can significantly impact costs, operational efficiency and customer satisfaction. Companies aim to manage inventory levels with supply chain partners to keep stock on hand at an optimal level while ensuring reliable customer service.

Inventory management can also provide other financial advantages, such as the ability to capitalise on volume prices from suppliers and accurately include the value of inventory in assets listed in company balance sheets and tax filings. More sophisticated inventory management systems can identify high- and low-performing products and trigger reorders when stock dwindles.

-

Pricing strategy: Setting an optimal price is part art, part science. Honing an effective strategy is critical, however, to manage the balance between supply and demand. For example, price cuts can stimulate sales during periods of low demand, helping you cover the fixed costs of production lines and your workforce.

-

Event management: This involves identifying all possible supply chain bottlenecks, breakdowns and delays at every link in the chain and developing contingency plans, such as workarounds, buffers and backups.

-

Integrated business planning (IBP): This is an approach that links your supply chain planning with the rest of your business, from sales and operations through finance. Because IBP gathers information from across the enterprise, it also can help companies perform better predictive analysis to grow the business and manage risk.

Award Winning

Cloud Inventory

7 Steps to Supply Chain Planning Success

Here are seven basic principles that leading supply chain planners adopt:

- Synchronise supply chain planning and execution, how often you update your data and planning horizons—or how far into the future your company will project.

- Systematically manage data so that you can use consistent information throughout your supply chain planning and management processes. This includes data about items, customers, manufacturing resources and suppliers.

- Build cooperative relationships with suppliers and primary customers so you can more easily adjust forecasts, orders and increase sales.

- Examine the data used in your demand planning for flaws, such as forecast errors or bias.

- Focus on actual point-of-sale data more than your company’s sales orders.

- Continuously analyse the product lifecycle, looking for ways to improve the links between product development and the supply chain.

- Create a culture of steady improvement to better understand customer behaviour.

Supply Chain Planning Trends

Despite the fact that companies increasingly use technology to improve supply chain planning

and management, demand forecasting remains a formidable challenge for many

organisations.

Companies are turning to predictive analytics to better understand buyer behaviour and other factors that influence demand. Predictive analytics is also becoming an important tool for planning the production, distribution and other supply chain functions needed to fulfill that demand.